Thinning Spinning

In the spinning process, not only change the shape of the blank, but also significantly change (thinning) its wall thickness is called strong spinning (also known as thinning spinning). The short and thick cylindrical blank set on the mandrel in the process of rotation, through the movement of the spinning wheel to apply a large external force and act on a small area, so that it produces plastic deformation. Since the metal being spun has a greater resistance to flow in the circumferential direction, it flows in the axial direction where the resistance is minimized and accumulates to form a long, thin-walled cylindrical part, which is therefore referred to as cylindrical part thinning spinning.

Load More

Back to TopSplit Spinning

A forming method using hardened sharp-edged rollers to gradually feed into the rectangular edge of a rotating circular blank, splitting it into a "Y" shape. Subsequent forming/shaping with 1-3 rollers achieves target dimensions. Suitable for aluminum alloys and round steel bars (heated) to produce integral V-groove pulleys and lightweight wheels. Widely used in automotive, agricultural machinery, washing machines, and batch manufacturing.

Load More

Back to TopFlanging and Curling Spinning

Flanging Spinning

A method to form flanges on tube ends using rollers, categorized into external/internal flanging. Specialized flange rollers (arc-shaped + cylindrical profiles) first push the edge into a curve via the arc section, then flatten it against the mold with the cylindrical section.

Hemming Spinning

Rolls workpiece edges into circular shapes using aesthetics. Rollers are selected based on the desired edge profile.hemming rollers with profile.

Load More

Back to TopReducing Diameter Spinning

A forming method that radially compresses hollow rotational parts or tubular blanks via spinning tools to reduce diameter. Workpieces are clamped on a mandrel (solid, composite, or coreless), exposing the forming area. During rotation, rollers follow programmed paths via control modes (CNC/mechanical) to progressively shrink the diameter into waist-drum shapes or closed spherical parts. To prevent wrinkling and cracking, the process is divided into multiple stages based on diameter reduction ratios, with incremental feed per pass. Mandrel swaps,intermediate heat treatment, or heating may apply. Wall thickness in necked zones varies: unchanged, thinned, or thickened, depending on material properties and shrinkage rate. Similar principles apply to hollow part open-end necking, with methods tailored to geometry, material, and quality standards.

Load More

Back to TopPlate Rotation

A forming process that reduces blank (sheet/preform) diameter through radial stretching. Unlike stretch forming, it uses a mandrel instead of a punch and spinning rollers instead of dies. As the most dominant and widely applied spinning method, bending-induced plastic deformation is its primary deformation mechanism. Compared to stretch forming, it offers greater flexibility in processing conditions, enabling production of complex rotationally symmetric shapes. Precise control of roller motion trajectories is critical, requiring deep expertise in roller movement mechanics.

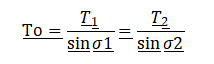

Thinning spinning refers to a method that maintains the blank’s outer diameter while altering its thickness to form axisymmetric

thin-walled parts such as cones (cone thinning spinning). Key characteristics include:

-Low roller forces due to localized deformation.

-Interdependent semi-cone angle and wall thickness.

-Smooth material flow, high surface finish, and superior dimensional accuracy.

-Compatibility with materials challenging for stretch spinning.

The theoretical formula governing the process is:

Load More

Back to TopGet the latest solutions for your business from your trusted cNc machine manufacturer

Contact Now